Harmonic Resolution Systems is comprised of a team of skilled engineers, dedicated craftsmen, and product support specialists with hundreds of years of experience in design, development, production, sales, and distribution of noise-reduction components and systems that brings the magic of your favorite music and movies to life in your home. These skills are utilized with passion at HRS to create products with exceptional performance and of the highest quality.

Our Chief Engineer, Mr. Michael Latvis, has over forty years of engineering and product development experience with a specialty in vibration, noise, and control systems. Prior to founding HRS in 1999, Mr. Latvis held a number of key positions with industry leading companies. These positions included Design Engineering, Engineering Management, and Business Development Management positions. Mr. Latvis has six issued patents related to shock, vibration isolation, and high-performance audio products. He has worked for a number of leading companies on the development of isolation products for audio systems, commercial aircraft, military aircraft, industrial applications, and missile defense systems.

HRS employs a wide range of technologies to achieve our unique level of performance. This includes the development of proprietary composite laminates and our custom HRS materials which are developed by skilled chemists and our engineers who are experts in creating structural materials with unique properties. These materials are developed based on decades of experience, product testing, and the guidance of our panel of listening experts. This approach allows HRS to custom engineer our products and adjust the material performance base on real world experience. It allows HRS to develop unique products and inspires our designs and refuse to settle for what is commercially available to all companies.

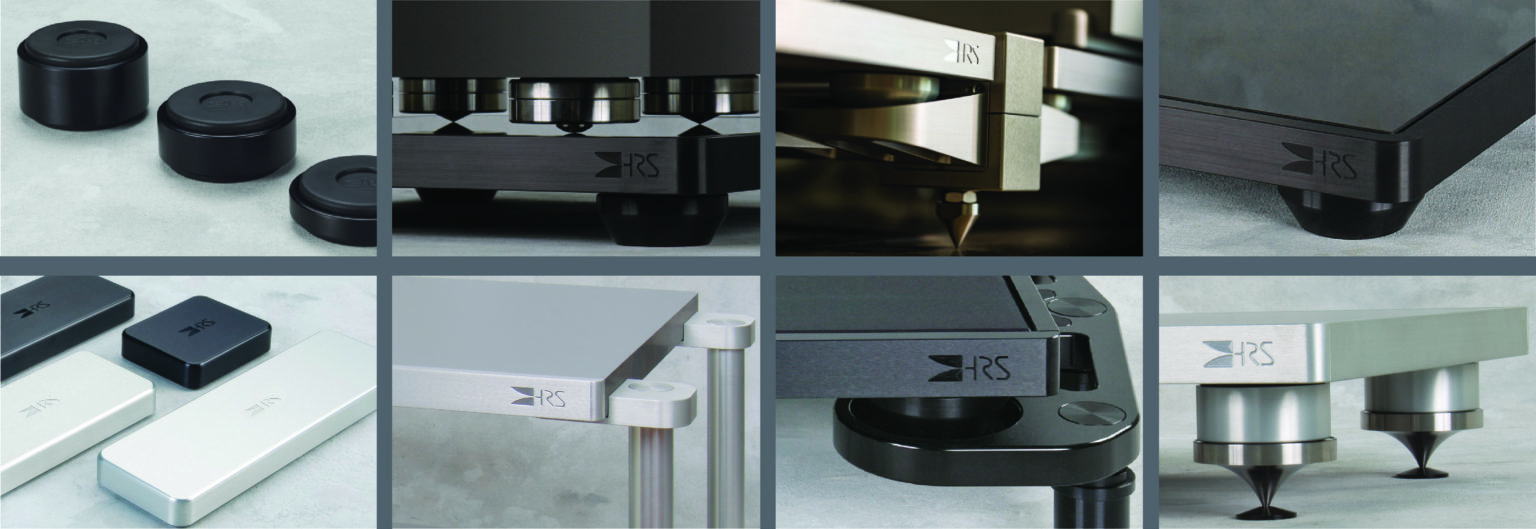

Skilled craftsmen using proprietary techniques and precision machinery produce our products. These craftsmen have a detailed understanding of manufacturing precision components and the quality systems required for producing the very highest quality products with consistent sonic results every time. They also hand finish and personally inspect every individual component. Modern technology combined with old world craftsmanship and values goes into every HRS product.

HRS believes that every part of our business is as equally important as the other. We are as dedicated to the use of precision tools and unique process as we are to old world craftsmanship and knowledge. We are dedicated to the design and sales support as we are to customer support and post-sales service. Our staff works diligently every day to build you a superior product and to ensure you an excellent long-term ownership experience. We look forward to working with you to create your high-performance entertainment system.

Advanced FEA design and analysis tools are used to design HRS products and verify stress, displacement, frequency response, and other key features prior to the initial production phase of our products. These tools combined with extensive listening tests result in superior product performance and a refined finished product when first released to production. When HRS releases a new product to production you are assured that you are receiving a refined production product that is well engineered and has also passed the approval of all the members of our listening panel.